Dave's Shaves Product Story

Each spokeshave that I make starts as a select, dimensioned blank of hardwood. Wood offerings for the shave models are listed on the order form. Substitutions on these may be made based on availability. Please inquire about upgrading to a figured or exotic wood species. Occasionally, a customer will supply a favorite wood for their shave. Please email or call me for feasibility and billet specs if this is an option you consider.

The modern spokeshave blades that I use are made to my specifications from O-1 high carbon steel by Hock Tools. These blades are sometimes referred to as cutters and the terms can be used interchangeably. What makes these blades "modern" and contrasts them to the original spokeshave blades, is that they are fabricated from plate steel, hardened, then outfitted with threaded tangs (posts). Each of these blades is identical, allowing replacements to "drop in".

Original spokeshave blades had square, friction fit tangs which appear to have been forged on a swedge block. The swedge block produced blades of uniform sizes, but they were all slightly different from each other. These differences were enough that shave makers needed to mark the blades and bodies with Roman Numerals to keep them matched during their manufacture. You will find these marks on the tang and throat areas of most original shaves.

Cutting depth adjustments on Dave's Shaves are made via top side accessible set screws*. This system uses long Allen screws threaded through the shave body. Earlier DS versions had flat head screws located under the blade. Their function is the same in either version: once a cutting depth is established, the blade is indexed and there is no need for further adjustments. If the blade is removed for sharpening, it will return exactly to its previous setting. No need to readjust and hunt for that sweet setting. Aluminum bosses or sleeves are next fitted to the top half of the post holes in the body. These sleeves provide a flat surface to help stabilize the brass nut and blade assembly. These features are standard on all Dave's Shaves.

Body profiles are next cut out, then brass wearplates are installed on the sole. Refinement of the throat and fitting the mouth opening is done by hand on every shave. The final step is shaping the body and finishing. Each of these bench-made shaves is sharpened and tested before it leaves the shop. These fine wooden spokeshaves are used internationally by both professional and recreational woodworkers.

* See Tips for blade adjustment instructions.

Dave's Shaves currently offers three spokeshave models

No. 1 Standard flatsole shave

Don't be surprised if this shave becomes the most reached for tool in your inventory. A traditional, centuries old design, this style of wooden spokeshave was at one time found in every woodworker's toolbox or shop.

The Standard shave has a flat sole and sports a brass wear plate. The modern, high carbon steel blade is made by Hock Tools to our specs. The blade is 1/8" thick and has a 2 3/4" cutting edge. It sharpens easily to an exquisite edge. The depth of cut is fully adjustable and indexed via set screws accessible from the top of the shave body. The body is made from select traditional hardwoods and is 11" overall. Sharp and ready to use, the No.1 combines comfort, performance and great looks!

No. 2 Compass shave

This spokeshave features a rounded sole and is the perfect tool for accessing inside curves or concave edges that a flat sole shave or handplane cannot reach. Examples of these kinds of areas are found on cabriole legs, shield style Windsor chair seats, and watercraft coamings. Decoy carvers and wood sculptors also favor this tool in their work.

The No.2 compass shave shares the traditional look and feel of original antique shaves of this type, but is of a stouter size utilizing the large Hock blade. This gives this shave a better feel and presence on larger work pieces. The No.2 shares the same body pattern as the No.1 Standard shave, uses the same blade adjustment features, and now has a brassed sole (previously an option).

No. 0 Compass shave

This is the "detail shave". Antique spokeshaves of this size are prized by those who use and are familiar with wooden spokeshaves. A small version of the No. 2 compass shave, this model allows one to access tight radii or perform delicate work. The #0 compass shave shares all the same modern performance features with the larger Dave's Shaves models. The body is shaped to patterns frequently seen in antique shaves of this size. The high performance Hock blade is 3/32" thick and a 1 1/2" wide cutting edge. The body has a brassed sole and is 9" overall.

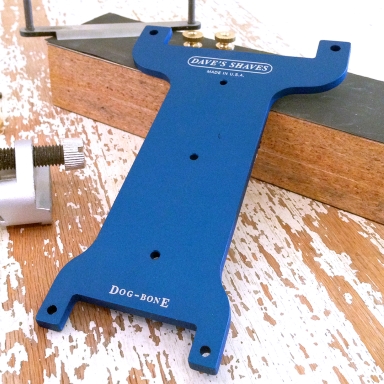

NEW! The Dog-Bone blade holder

Sharpening or honing the spokeshave blades used by Dave's Shaves can be a challenge. The size and shape of these blades make hand-holding them difficult and almost impossible to use with most commercially available honing guides or jigs. The Dave's Shaves "Dog-Bone" blade holder solves this problem.

The Dog-Bone will fit most honing guides or jigs that accept a 2" chisel. The Dog-Bone works equally well with sharpening jigs on abrasive wheels. The spokeshave blade is simply attached to the Dog-Bone with the brass spokeshave nuts. This creates an assembly with a longer, broader surface that is easily clamped into the honing guide or jig. The Dog-Bone will accept both the large and small size spokeshave blades, either with fixed-tangs or thumbscrews. The Dog-Bone is made of aluminum and has an anodized finish.

(The blades, honing guide and sharpening block are not included).